What are some common construction mistakes and how can they be avoided?

Construction projects can be complex, and mistakes can lead to costly delays, safety hazards, and structural failures. Here are some common construction mistakes and how to avoid them:

- Poor Planning and Design Flaws

- Mistake: Inadequate site analysis, incorrect load calculations, or flawed architectural designs.

- Solution: Conduct thorough site assessments, hire experienced architects and engineers, and use Building Information Modeling (BIM) for detailed planning.

- Incorrect Material Selection

- Mistake: Using substandard or inappropriate materials for the project’s environmental and structural needs.

- Solution: Follow specifications from structural engineers, source high-quality materials, and ensure compliance with industry standards.

- Weak Foundation Work

- Mistake: Insufficient soil testing, poor compaction, or incorrect footing size.

- Solution: Conduct proper soil testing, use appropriate foundation design, and ensure proper curing and reinforcement.

- Poor Quality Control and Workmanship

- Mistake: Lack of skilled labor, improper mixing of concrete, or rushed construction processes.

- Solution: Hire qualified workers, implement strict quality control measures, and conduct regular inspections.

- Ignoring Safety Standards

- Mistake: Lack of proper safety gear, weak scaffolding, or inadequate training.

- Solution: Enforce OSHA or local safety regulations, provide protective equipment, and conduct regular safety training.

- Improper Waterproofing and Drainage

- Mistake: Failing to waterproof basements, roofs, or install proper drainage systems.

- Solution: Use waterproofing membranes, ensure proper sloping and drainage design, and install gutters and downspouts correctly.

- Mismanagement of Budget and Resources

- Mistake: Underestimating costs, leading to project delays and low-quality substitutions.

- Solution: Prepare a realistic budget, include contingencies, and track expenses regularly.

- Poor Communication and Coordination

- Mistake: Miscommunication between stakeholders leading to delays and rework.

- Solution: Use project management software, hold regular meetings, and ensure clear documentation.

- Skipping Necessary Permits and Regulations

- Mistake: Starting construction without proper approvals, leading to legal issues.

- Solution: Research and obtain all necessary permits before beginning construction.

- Ignoring Environmental Factors

- Mistake: Not considering wind loads, seismic activity, or local climate conditions.

- Solution: Adapt designs based on environmental studies and use sustainable building materials.

- Improper Concrete Curing

- Mistake: Rushing the curing process, leading to cracks and reduced strength.

- Solution: Allow proper curing time (at least 7 days for normal concrete), keep the surface moist, and use curing compounds if needed.

- Inaccurate Measurements and Cutting Errors

- Mistake: Miscalculations in dimensions leading to misalignment and rework.

- Solution: Double-check measurements, use precise tools, and ensure workers follow blueprints correctly.

- Weak Structural Connections

- Mistake: Incorrectly securing beams, columns, or joints, which can lead to structural failure.

- Solution: Use appropriate fasteners, bolts, and reinforcement as per engineering specifications. Inspect joints regularly.

- Improper Reinforcement Placement

- Mistake: Reinforcement bars (rebar) not placed at the correct depth or spacing, leading to weak concrete structures.

- Solution: Follow engineering drawings strictly, use rebar spacers, and verify positioning before pouring concrete.

- Insufficient Insulation

- Mistake: Not installing enough insulation, leading to high energy costs and poor thermal comfort.

- Solution: Use high-quality insulation materials suitable for the climate and building use. Ensure full coverage in walls, floors, and roofs.

- Overlooking Expansion Joints

- Mistake: Failing to include expansion joints, causing cracks due to temperature changes.

- Solution: Incorporate properly spaced expansion joints in concrete and structural elements to accommodate movement.

- Poor Masonry Work

- Mistake: Inconsistent mortar thickness, improper brick alignment, or weak adhesion.

- Train masons on correct techniques, use the proper mortar mix, and follow alignment guidelines.

- Electrical Wiring Mistakes

- Mistake: Overloading circuits, using undersized wires, or improper grounding, leading to fire hazards.

- Solution: Follow electrical codes, use the correct wire gauge, and have an electrician inspect the installation.

- Plumbing Installation Errors

- Mistake: Incorrect pipe slopes, weak joints, or poor waterproofing, leading to leaks and drainage issues.

- Solution: Use high-quality pipes, ensure proper sloping (e.g., 1/4 inch per foot for drainage), and test for leaks before sealing walls.

- Weak Roofing Installation

- Mistake: Using low-quality materials, improper sealing, or not securing roofing components properly.

- Solution: Follow manufacturer guidelines, install proper flashing, and use high-quality fasteners to prevent leaks and wind damage.

- Ignoring Seismic and Wind Loads

- Mistake: Not designing buildings to withstand earthquakes or strong winds, causing structural failure.

- Solution: Follow local building codes for seismic and wind resistance, use flexible joints, and reinforce weak points.

- Poor HVAC System Placement and Sizing

- Mistake: Installing an undersized or oversized HVAC system, leading to inefficiency and high energy costs.

- Solution: Conduct load calculations, use energy-efficient HVAC units, and place them in well-ventilated areas.

- Not Testing Before Finalizing Work

- Mistake: Skipping system tests (electrical, plumbing, HVAC) before completing the project.

- Solution: Conduct thorough inspections and functional tests before handing over the project.

- Unprotected Steel from Corrosion

- Mistake: Exposing steel components to moisture without proper coatings, leading to rust and deterioration.

- Solution: Use galvanized or coated steel, apply protective paints, and ensure proper drainage around steel structures.

- Cutting costs in the wrong areas.

- Mistake: Using cheap materials or unqualified labor to save money, leading to long-term failures.

- Solution: Balance cost savings with quality. Invest in skilled labor and durable materials to avoid costly repairs later.

Residential Construction Mistakes & Solutions

- Poor Site Preparation

- Mistake: Failing to clear the site properly or ignoring soil conditions, leading to foundation issues.

- Solution: Conduct thorough site assessments, soil testing, and grading before construction begins.

- Weak Foundation Work

- Mistake: Using the wrong concrete mix, poor compaction, or inadequate footings.

- Solution: Use high-quality concrete, ensure proper curing, and follow engineering recommendations for depth and reinforcement.

- Improper Waterproofing

- Mistake: Leaky basements, damp walls, or roof leaks due to poor waterproofing.

- Solution: Apply waterproof membranes, seal joints properly, and install drainage systems like French drains or sump pumps.

- Incorrect Window and Door Installation

- Mistake: Poor alignment, gaps, or lack of insulation, leading to energy loss and drafts.

- Solution: Ensure correct measurements, use high-quality seals, and install energy-efficient windows and doors.

- Bad Plumbing Layout

- Mistake: Poorly planned water lines, incorrect pipe slopes, or insufficient water pressure.

- Solution: Design plumbing systems with correct pipe sizes, slopes, and pressure considerations before installation.

- Overlooking Ventilation Needs

- Mistake: Poor airflow in kitchens, bathrooms, or attics, leading to mold and heat buildup.

- Install proper ventilation fans, ridge vents, and ensure air circulation with well-placed windows.

- Insufficient Insulation

- Correction: Inadequate wall and attic insulation causing high energy costs.

- Correction: Use quality insulation materials like spray foam, fiberglass, or rigid board insulation, ensuring proper R-value for the climate.

- Electrical Wiring Mistakes

- Correction: Overloaded circuits, exposed wires, or improper breaker sizing.

- Solution: Hire a certified electrician, follow local codes, and ensure safety inspections before finalizing.

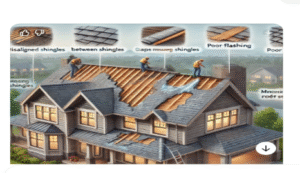

- Improper Roofing Installation

- Mistake: Weak shingles, improper flashing, or inadequate roof pitch leading to leaks.

- Solution: Use high-quality roofing materials, ensure correct flashing installation, and design slopes for proper drainage.

Here is an image illustrating improper roofing installation, highlighting common mistakes like misaligned shingles, poor flashing, gaps, and sagging sections.

- Ignoring Expansion and Contraction in Materials

- Mistake: Wood flooring buckling or concrete cracking due to weather changes.

- Solution: Allow expansion gaps in flooring, use proper concrete joints, and choose materials suited for local weather conditions.

Commercial Construction Mistakes & Solutions

- Poor Space Planning

- Inefficient use of space, lack of accessibility, or failure to accommodate business needs.

- Solution: Work with experienced architects, follow accessibility regulations, and optimize layouts for function and flow.

- Weak Structural Design

- Correction: Undersized beams, columns, or failure to consider wind and seismic loads.

- Solution: Follow structural engineering calculations, use proper load-bearing materials, and incorporate earthquake-resistant designs where necessary.

- HVAC System Miscalculations

- Correction: Incorrect system sizing leading to inefficient cooling/heating.

- Solution: Perform accurate load calculations, use energy-efficient HVAC units, and ensure proper duct placement.

- Inadequate Fire Safety Measures

- Mistake: Missing fire exits, lack of sprinklers, or incorrect fire-rated materials.

- Solution: Follow fire codes, install fire suppression systems, and use fire-resistant materials for walls and ceilings.

- Poor Acoustic Insulation

- Mistake: Excess noise in office buildings, hotels, or conference halls due to poor soundproofing.

- Solution: Use acoustic panels, soundproof insulation, and strategic wall placements to minimize noise transfer.

- Incorrect Elevator Installation

- Mistake: Improper alignment, unsafe speed settings, or mechanical failures.

- Solution: Hire certified elevator technicians, conduct safety tests, and follow regulatory codes.

- Lack of Energy Efficiency Considerations

- Mistake: Excessive energy consumption due to inefficient lighting, HVAC, and windows.

- Solution: Use LED lighting, automated energy controls, and double-glazed windows for better efficiency.

- Non-Compliance with Zoning Laws & Permits

- Mistake: Construction delays due to legal violations.

- Solution: Obtain all necessary permits, consult legal experts, and adhere to local zoning regulations.

- Poor Parking and Traffic Flow Design

- Mistake: Insufficient parking spaces or poor traffic circulation around the building.

- Solution: Design parking with adequate capacity, clear signage, and optimized traffic flow patterns.

- Using Low-Quality Materials to Cut Costs

- Using substandard materials that deteriorate quickly, leading to high maintenance costs.

- Solution: Invest in durable materials that offer longevity and require minimal maintenance over time.

For your residential construction project, here’s a breakdown of key considerations and best practices for material selection, cost control, energy efficiency, and structural durability:

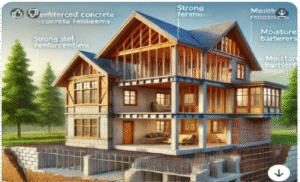

Here is an illustration showcasing structural durability in a residential building, highlighting reinforced concrete beams, steel framework, moisture barriers, and earthquake-resistant features.

- Material Selection

Choosing the right materials ensures quality, durability, and cost-effectiveness.

- Foundation & Structure: Use reinforced concrete for strength and longevity. For walls, concrete blocks are cost-effective, while bricks provide better insulation.

- Roofing: Consider metal sheets (durable and energy-efficient) or clay tiles (long lifespan and better insulation).

- Flooring: Ceramic tiles for affordability and low maintenance, engineered wood for warmth, or polished concrete for durability.

- Windows & Doors: UPVC windows for energy efficiency and low maintenance, solid wood or steel doors for security.

- Paint & Finishes: Use weather–resistant, non-toxic paints for better indoor air quality and longevity.

- Cost Control

Keeping costs within budget without compromising quality is key.

- Budget Planning: Start with a detailed cost estimate, including materials, labor, and contingency funds (10-15% extra for unexpected costs).

- Bulk Purchasing: Buy materials in bulk to get discounts but avoid over-purchasing to reduce waste.

- Alternative Materials: Consider engineered wood instead of hardwood, fiber cement boards instead of plywood, and precast concrete instead of poured concrete to cut costs.

- Minimize Waste: Plan cuts for materials efficiently and recycle leftover materials where possible.

- Energy Efficiency:

Reducing energy use saves money in the long run and creates a comfortable home.

- Insulation: Use foam board or fiberglass insulation in walls, roofs, and floors to maintain indoor temperature.

- Windows & Ventilation: Install double–glazed windows and design cross-ventilation for natural cooling.

- Solar Power: Invest in solar panels to reduce electricity bills.

- Energy–Efficient Lighting: Use LED bulbs instead of incandescent lights.

- Smart Appliances: Choose energy–efficient air conditioners, water heaters, and refrigerators.

- Structural Durability:

A durable home minimizes maintenance costs and lasts for generations.

- Foundation Strength: Ensure proper soil testing, use waterproofing, and reinforce with steel bars.

- Roof Design: Use a sloped roof to prevent water accumulation and extend lifespan.

- Pest Resistance: Use treated wood and anti-termite coatings to prevent damage.

- Moisture Protection: Use waterproof cement and good drainage systems to avoid damp walls and leaks.

- Earthquake & Wind Resistance: If in a high-risk area, reinforce walls and use braced frames or shear walls.