Types of iron bars to use while building and when they are used in different stages of construction.

Iron bars (reinforcement bars or rebars) are essential in construction to provide tensile strength to concrete, which is strong in compression but weak in tension. Different types of iron bars are used at various construction stages based on structural requirements. Here are the main types and their uses:

Types of Iron Bars and Their Uses in Construction:

-

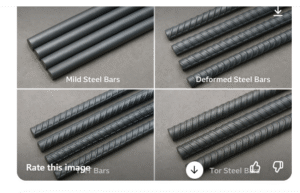

- Mild Steel Bars (MS Bars)

- Description: Plain round bars with a smooth surface, low tensile strength, and lower bonding ability with concrete.

- Use: Generally used in small-scale construction, temporary structures, and non-load-bearing structures.

- Mild Steel Bars (MS Bars)

- Deformed Steel Bars (High Yield Strength Deformed Bars – HYSD)

-

- Description: Bars with lugs or ribs to enhance bonding with concrete. They have higher tensile strength than mild steel bars.

- Use: Widely used in reinforced concrete structures such as beams, slabs, columns, and footings.

- Thermo-Mechanically Treated Bars (TMT Bars)

- Description: High-strength bars with excellent ductility, corrosion resistance, and earthquake resistance.

- Use: Used in all structural elements, including foundations, columns, beams, slabs, and bridges.

- Tor Steel Bars

- Description: A type of deformed steel bar with high yield strength and good bonding capacity with concrete.

- Use: Suitable for heavy structural applications such as high-rise buildings and bridges.

- Epoxy-Coated Rebars

- Description: Steel bars coated with epoxy to prevent corrosion.

- Use: Used in coastal and marine environments, bridges, and water-retaining structures.

- Stainless Steel Rebars

- Description: Highly corrosion-resistant rebars used in special projects where durability is critical.

- Use: Used in marine structures, wastewater treatment plants, and hospitals.

- Galvanized Rebars

- Description: Steel bars coated with zinc for better corrosion resistance.

- Used in humid and corrosive environments, such as bridges and underground structures.

- Fiber-Reinforced Polymer (FRP) Bars

- Non-metallic rebars made from glass, carbon, or basalt fiber.

- Used in projects where corrosion is a major concern, such as chemical plants and water tanks.

Use of Iron Bars at Different Stages of Construction:

| Construction Stage | Type of Iron Bar Used | Purpose |

|---|---|---|

| Foundation & Footing | TMT Bars, HYSD Bars | Provide strength to withstand loads and prevent settlement. |

| Columns & Beams | TMT Bars, Deformed Bars | Carry vertical and horizontal loads to distribute weight evenly. |

| Slabs & Roofs | TMT Bars, Deformed Bars | Support the load of flooring, roofing, and occupants. |

| Retaining Walls | TMT Bars, Epoxy-Coated Bars | Withstand soil pressure and water force in basements and underground structures. |

| Bridges & Highways | Stainless Steel Bars, Epoxy-Coated Bars | Prevent corrosion and enhance durability in harsh environments. |

| Marine & Coastal Structures | FRP Bars, Stainless Steel Bars | Prevent rusting in saline conditions. |

Final Thoughts

For residential and commercial buildings, TMT bars are the most commonly used due to their superior strength, flexibility, and resistance to corrosion. Selecting the right type of iron bar depends on load requirements, environmental conditions, and durability needs.

Types of iron bars to use while building and when they are used in different stages of construction

Iron bars (reinforcement bars or rebars) are essential in construction to provide tensile strength to concrete, which is strong in compression but weak in tension. Different types of iron bars are used at various construction stages based on structural requirements. Here are the main types and their uses:

Types of Iron Bars and Their Uses in Construction:

-

- Mild Steel Bars (MS Bars)

- Description: Plain round bars with a smooth surface, low tensile strength, and lower bonding ability with concrete.

- Use: Generally used in small-scale construction, temporary structures, and non-load-bearing structures.

- Deformed Steel Bars (High Yield Strength Deformed Bars – HYSD)

- Bars with lugs or ribs to enhance bonding with concrete. They have higher tensile strength than mild steel bars.

- Use: Widely used in reinforced concrete structures such as beams, slabs, columns, and footings.

- Thermo-Mechanically Treated Bars (TMT Bars)

- Description: High-strength bars with excellent ductility, corrosion resistance, and earthquake resistance.

- Use: Used in all structural elements, including foundations, columns, beams, slabs, and bridges.

- Tor Steel Bars

- Description: A type of deformed steel bar with high yield strength and good bonding capacity with concrete.

- Use: Suitable for heavy structural applications such as high-rise buildings and bridges.

- Epoxy-Coated Rebars

- Description: Steel bars coated with epoxy to prevent corrosion.

- Use: Used in coastal and marine environments, bridges, and water-retaining structures.

- Stainless Steel Rebars

- Description: Highly corrosion-resistant rebars used in special projects where durability is critical.

- Use: Used in marine structures, wastewater treatment plants, and hospitals.

- Galvanized Rebars

- Description: Steel bars coated with zinc for better corrosion resistance.

- Use: Used in humid and corrosive environments, such as bridges and underground structures.

- Mild Steel Bars (MS Bars)

- Fiber-Reinforced Polymer (FRP) Bars

-

- Description: Non-metallic rebars made from glass, carbon, or basalt fiber.

- Use: Used in projects where corrosion is a major concern, such as chemical plants and water tanks.

Use of Iron Bars at Different Stages of Construction: Final Thoughts

For residential and commercial buildings, TMT bars are the most commonly used due to their superior strength, flexibility, and resistance to corrosion. Selecting the right type of iron bar depends on load requirements, environmental conditions, and durability needs.

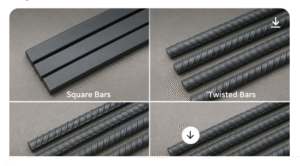

Those are some images showcasing different types of iron bars used in construction.

Thank you for this informative article! The breakdown of iron bar types like TMT and HYSD, along with their specific uses in foundations and columns, is very clear and helpful. It’s great to see practical insights for construction projects in Uganda. Could you share more about how to choose the right TMT bar grade for residential buildings in Kampala’s climate?

Thank you so much Mr. Joel for the positive comment. I will definitely get back to you with answers to your question.

Great question—picking the right TMT (thermo-mechanically treated) bar grade is one of the biggest levers you have for durability and safety, especially in Kampala’s warm, humid, and rainy climate.

Quick answer (what most homes use)

• Go-to grade: Fe500D (or B500C under BS/Eurocode naming).

o It gives a strong blend of strength (500 MPa) and ductility (“D”/“C”), which is ideal for residential buildings in our region’s humidity and moderate seismicity.

• When to step up: Fe550D (or B500C/B550C) only if your structural engineer designs for it (e.g., longer spans, heavy loads, or where reducing bar count/congestion helps).

• Avoid: Non-ductile variants (e.g., Fe500 without “D”) for primary members—ductility matters for crack control and energy dissipation.

Why this fits Kampala’s conditions

• Humidity & rainfall: Higher corrosion risk. You want a ductile grade (better crack control), adequate concrete cover, and good mix quality to slow corrosion.

• Temperature: Warm but not extreme—no special high-temperature steel needed.

• Seismicity: Not high like coastal subduction zones, but the region isn’t zero-risk. Ductility is cheap insurance.

Grade cheat sheet

• Fe415 / B420: Easier to bend, but lower strength—often leads to more steel and congestion. Fine for light works; most modern homes now go higher.

• Fe500 / B500: Strong, common. Choose Fe500D / B500C for better ductility (preferred).

• Fe550D / B550C: Higher strength with ductility—use if the design takes advantage (fewer bars, thinner members). Needs tighter quality control on anchorage and detailing.

“D”/“C” = higher ductility class (better elongation and bending performance). In practice, pick the ductile variant of whatever strength you choose.

Member-wise pointers (typical residential ranges—final call by your engineer)

• Slabs: 8–12 mm bars, Fe500D; spacing per design.

• Beams: 12–20 mm main bars in Fe500D; stirrups 8–10 mm Fe500D.

• Columns: 16–25 mm Fe500D main bars; ties 8–10 mm. Consider Fe550D if column congestion is a problem and design allows.

• Footings: 12–20 mm Fe500D; ensure proper cover (usually ≥50–75 mm depending on exposure and code).

• Masonry reinforcement (lintels, ring beams): 8–12 mm Fe500D.

Corrosion & durability (critical for Kampala)

1. Concrete cover: Don’t skimp. Use spacers; typical residential covers:

o Slab/beam: 20–30 mm (check code/exposure category)

o Columns/walls: 25–40 mm

o Footings: 50–75 mm

2. Concrete quality:

o Target at least C25/30 for primary members (or per your engineer).

o Keep w/c ratio ≤ 0.50; proper compaction and curing (7–14 days) matter more than fancy admixtures.

3. Bar protection options:

o Epoxy-coated or galvanized bars help if your site has persistent dampness, aggressive soils, or poor drainage.

o Otherwise, good cover + dense concrete is usually enough for residential budgets.

4. Detailing for crack control: Closer stirrup spacing near supports, proper lap/anchor lengths, and ductile grade reduce crack widths (hence corrosion pathways).

5. Site practice: Store bars off the ground, covered. Light uniform rust is okay; reject pitted/flaky rust.

Procurement & verification (Uganda context)

• Ask for mill test certificates (yield strength, elongation, bend/rebend test, chemical composition/CE).

• Prefer ductile class (D/C) and low carbon equivalent (CE ≤ ~0.42) for better weldability and bendability.

• Check weight per meter and rib pattern consistency (spot fake/under-sized bars).

• Where possible, buy from suppliers with UNBS certification and recent third-party test reports.

Simple decision flow

1. Typical single-/double-stored home? → Fe500D (B500C) for all primary members.

2. Heavier loads/long spans or bar congestion? → Consider Fe550D where design benefits.

3. Aggressive moisture/poor drainage site? → Keep Fe500D, but improve cover, concrete quality, and consider epoxy/galvanized for the worst-exposed elements.

4. Tight budget? → still choose ductile grade; save money via good detailing, correct bar sizes, and minimizing waste—not by downgrading ductility.

Practical tips to discuss with your engineer

• Anchorage & laps: Higher grades often need longer development lengths—detail accordingly.

• Bending on site: Use proper benders; minimum bend diameters per code (e.g., 4d–6d for stirrups; larger for main bars).

• Mix + cover before grade: A perfect Fe550D bar in porous, under-cured concrete will still corrode; prioritize the concrete and cover first.

TMT bar Selection & Use Guide – Kampala Climate (Residential)

Recommended Grade

• Fe500D (B500C) → Best for most homes (strength + ductility).

• Fe550D → only if engineer specifies (long spans, heavy loads, bar congestion).

• Avoid plain Fe500 → always choose the Ductile (D/C) version.

Member-wise Bar Use (Typical Residential)

• Slabs: 8–12 mm, Fe500D

• Beams: 12–20 mm Fe500D (main); 8–10 mm (stirrups)

• Columns: 16–25 mm Fe500D (main); 8–10 mm (ties)

• Footings: 12–20 mm Fe500D (main)

• Lintels/Ring Beams: 8–12 mm Fe500D

(Engineer’s drawings always override this guide.)

Durability in Kampala’s Climate

• Concrete Cover

o Slabs/Beams: 20–30 mm

o Columns/Walls: 25–40 mm

o Footings: 50–75 mm

• Concrete Quality: C25/30 minimum, w/c ≤ 0.5

• Curing: Keep concrete moist for 7–14 days

• Reinforcement Storage: Raise bars off the ground, cover against rain.

• Reject bars with deep rust, pits, or irregular ribs.

Detailing Tips

• Laps/Anchorage: Longer for higher grades—check code.

• Stirrups/Ties: Closer spacing near supports.

• Bending: Use proper bar benders, min. bend diameter = 4d–6d.

Procurement Checklist

✔ UNBS-certified supplier

✔ Mill test certificate (yield strength, elongation, bend/rebend)

✔ Check bar weight per meter & rib pattern

✔ Low CE (≤0.42) = better bendability/weldability

Final Takeaway

• Fe500D is the sweet spot for Kampala homes.

• Protect steel with good concrete + cover before thinking of higher grades.

• Always follow engineer’s drawings + site QC.